Propulsion

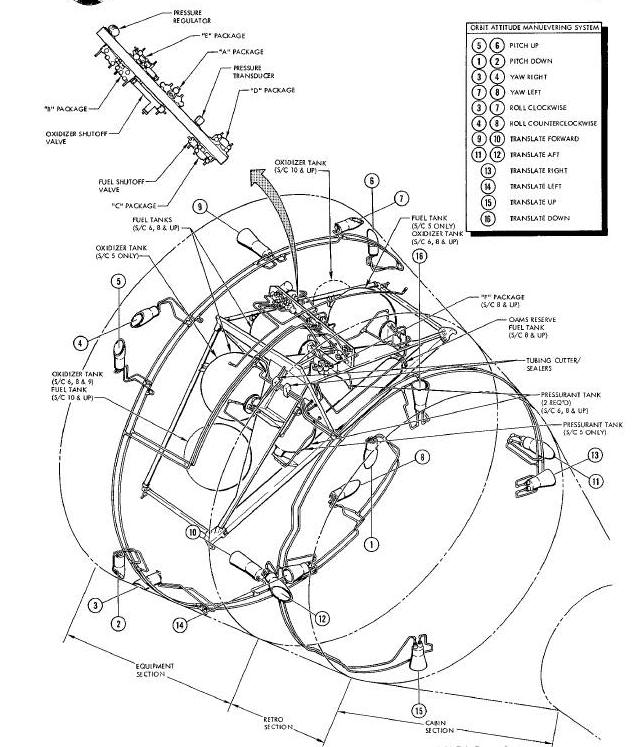

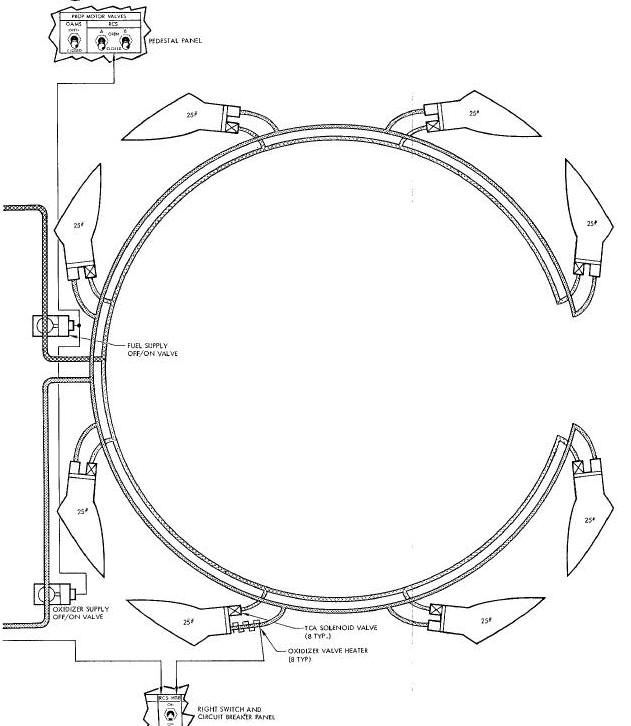

Orbit Attitude Maneuvering System and TCA Location Diagram

ORBIT ATTITUDE AND MANUVERING SYSTEM

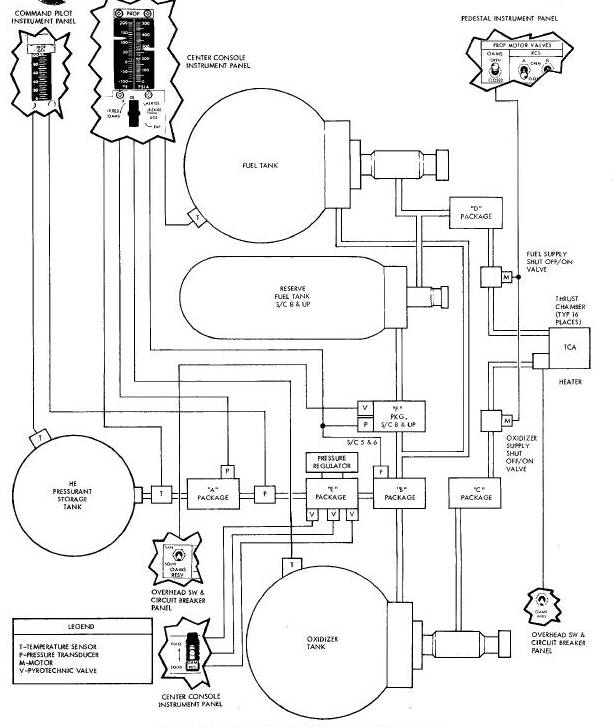

OAMS Control and Indicator Schematic

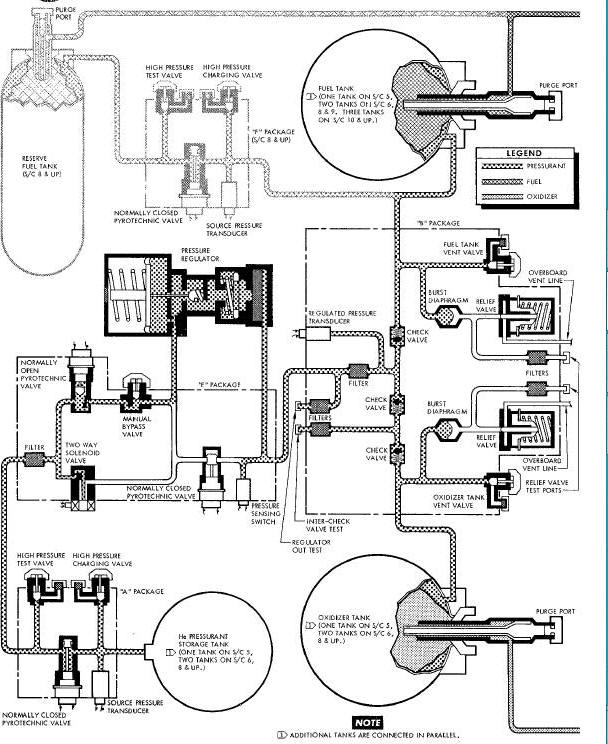

Orbit Attitude Maneuvering System Schematic

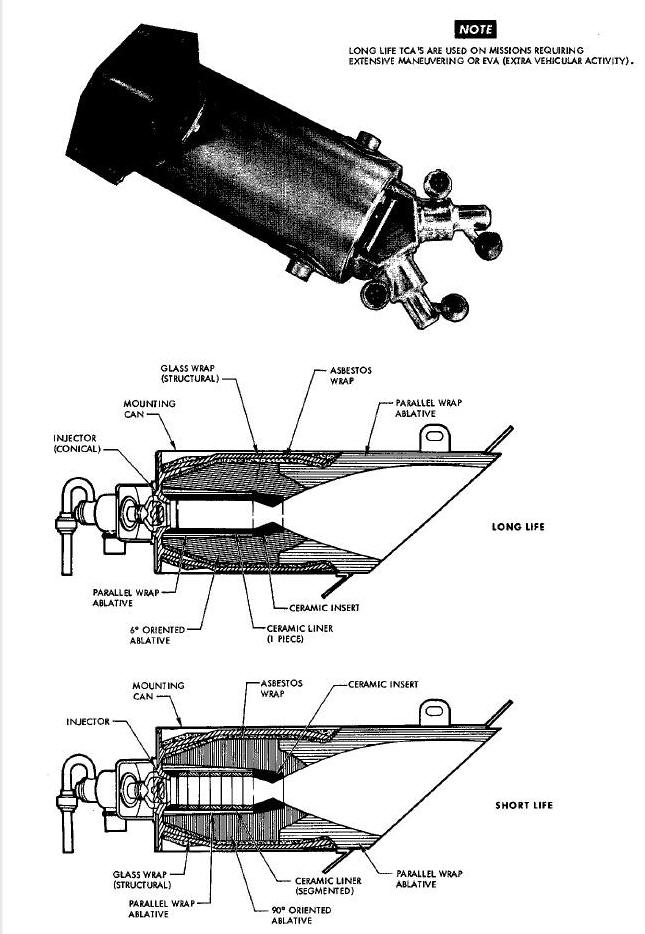

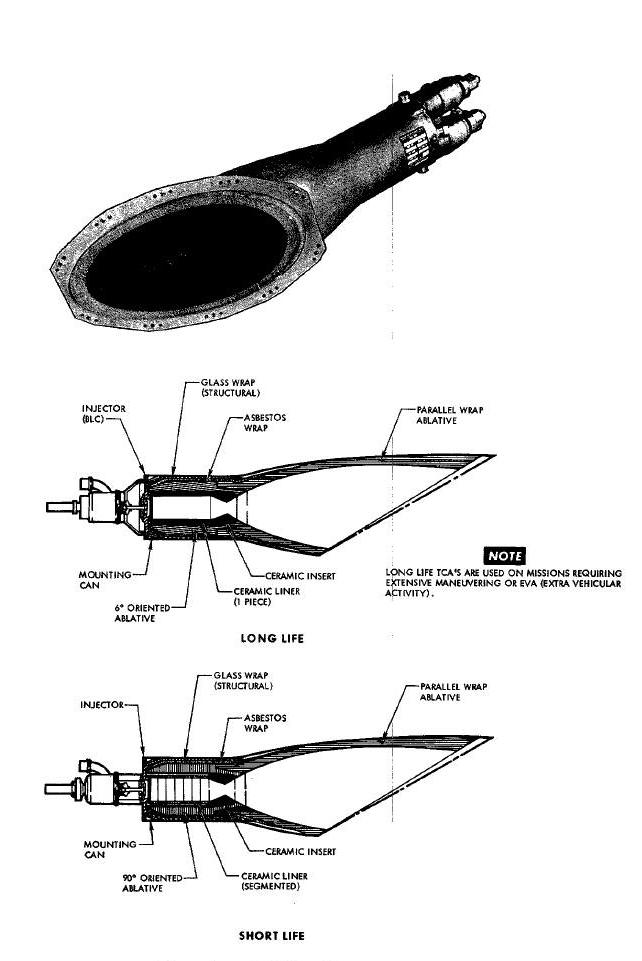

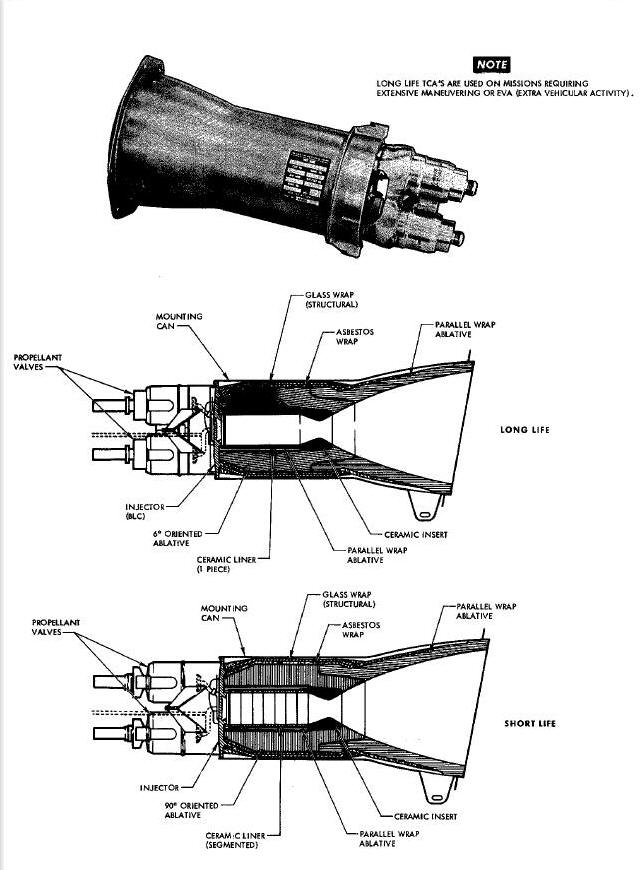

Thrust Chamber Assembly (TCA) Group

Thrust Chamber Assembly (TCA) Group

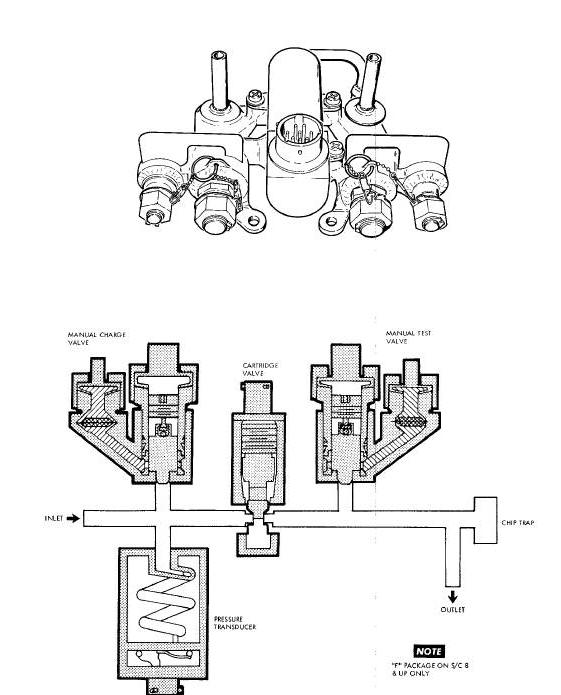

OAMS and RCS "A" Package and OAMS "F" Package Diagram

"F" Package (Spacecraft 8 thru 12 Only)

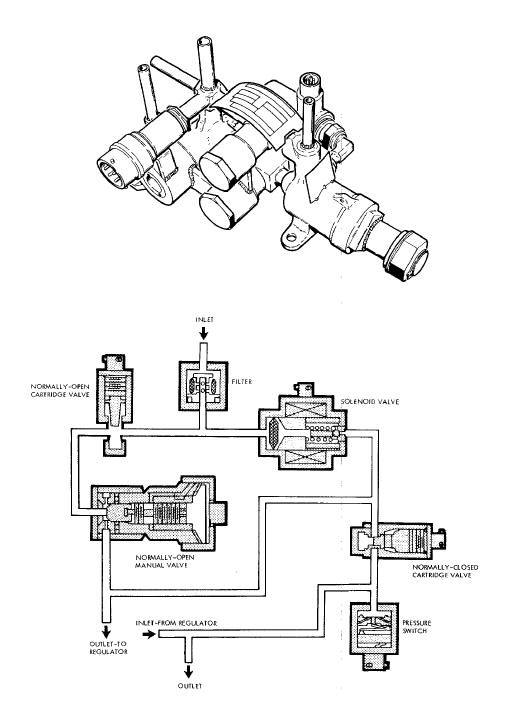

OAMS and RCS Pressure Regulator Diagram

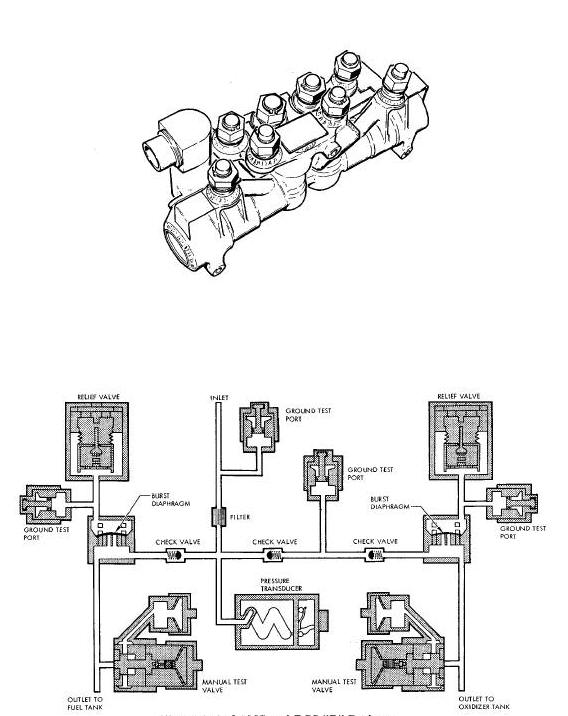

OAMS and RCS "B" Package Diagram

Reserve Fuel Tank (Spacecraft 8 thru 12 only)

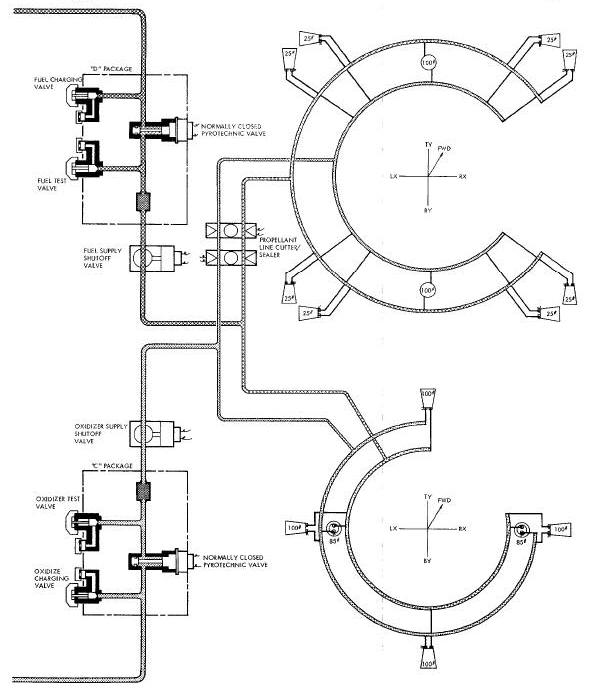

OAMS and RCS "C" and "D" Package Diagram

Propellant Supply Shutoff Valves

OAMS and RCS Propellant Shutoff Valve Diagram

Thrust Chamber Assembly (TCA) Group

Re-Entry Control "A" and "B" Systems Diagram

Thrust Chamber Assembly (TCA) Group

Thrust Chamber Assembly (TCA) Group

Propellant Supply Shutoff Valves

The Gemini Spacecraft is provided with an attitude and maneuvering

control capability. (Figure Below). This control capability is used

during the entire spacecraft mission, from the time of launch vehicle

separation until the reentry phase is completed. Spacecraft control is

accomplished by two rocket engine systems, the Orbit Attitude and

Maneuvering System (OAMS) and the Re-entry

Control System (RCS).

Orbit Attitude Maneuvering System and TCA Location Diagram

The OAMS controls the spacecraft attitude and provides maneuver

capability from the time of launch vehicle separation until the

initiation of the retrograde phase of the mission. The RCS provides

attitude control for the re-entry module during the re-entry phase of

the mission. The 0AMS and RCS respond to electrical commands from the

Attitude Control Maneuvering Electronics (ACME) in the

automatic mode or from the crew in the manual mode.

ORBIT ATTITUDE AND MANUVERING SYSTEM

The Orbit Attitude Maneuvering System (OAMS) (Figure Above) is a fixed thrust, cold gas pressurized, storable liquid, hypergolic bi-propellant, self contained propulsion system which is capable of operating in the environment outside the earth's atmosphere. Maneuvering capability is obtained by firing thrust chamber assemblies (TCA) singly or in groups. The thrust chamber assemblies are mounted at various points about the adapter in locations consistent with the modes of rotational or translation acceleration required.

OAMS Control and Indicator Schematic

The OAMS provides a means of rotating the spacecraft about its three attitude control axes (roll, pitch, and yaw) and translation control in six directions (right, left, up, down, forward and aft). The combination of attitude and translational maneuvering creates the capability of rendezvous and docking with another space vehicle in orbit.

The primary purpose of OAMS is spacecraft control in orbit. The OAMS

is also used, after firing of shaped charges, to separate the Spacecraft

from the launch vehicle during a normal launch or in case of an abort

which may occur late in the launch phase. During initiation of

retrograde sequence, tubing cutter/sealer devices sever and seal the

propellant feed lines from the equipment adapter. All

of the OAMS (except six TCA's located in retro section) are separated

from the spacecraft with the equipment section of the adapter.

Spacecraft control functions are then assumed by the Re-entry Control

System (RCS). OAMS control units and tanks are mounted on a structural

frame (module concept) in the equipment section. The control units

consist of forged and welded "packages" Each package consists of several

functioning components and filters. The OAMS Control and Indicator

Schematic (Figure Below) is a simplified schematic of the indicators and

manual controls which are directly related to the Propulsion System.

Additional controls

are provided by the Attitude Control and Maneuvering Electronics (ACME)

System The delivery of pressurant, fuel and oxidizer is accomplished by

a uniquely brazed tubing manifold system. The OAMS system is divided

into three groups; pressurant group, fuel/oxidizer group and Thrust

Chamber Assembly (TCA) group.

The pressurant group (Figure below) consists of a pressurant tank,

"A" package, "E" package, "F" package on Spacecraft 8 thru 12, pressure

regulator, and "B" package. Inlet valves, ports and test ports are

provided at accessible points to permit servicing, venting, purging and

testing. Filters are provided throughout the system to prevent

contamination of the system. The pressurant is isolated

in the storage tank during pro-launch periods by a normally closed

pyrotechnic actuated valve, located in the "A" package. On Spacecraft 8

thru 12, the pressurant is isolated from the reserve fuel tank by the

"F" package.

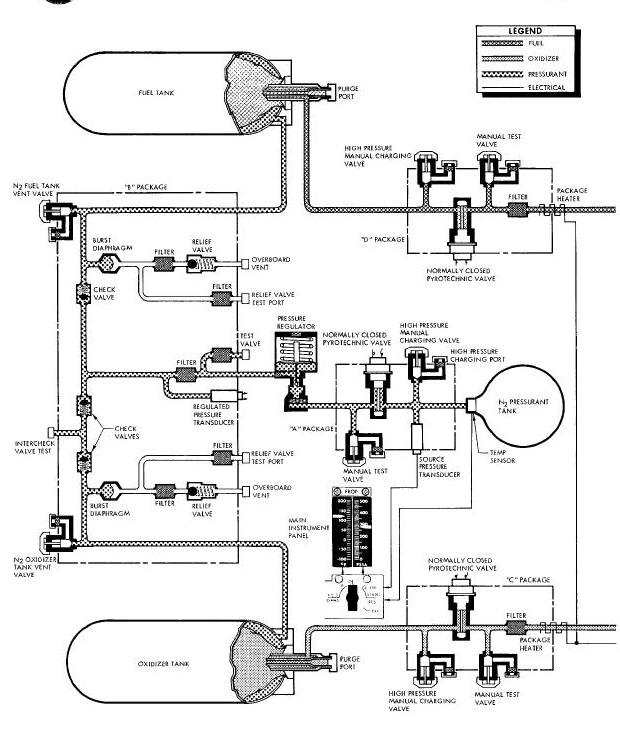

Orbit Attitude Maneuvering System Schematic

The fuel/oxidizer (propellant) group (Figure

Above) consists of expulsion bladder storage tanks, "C" and "D"

packages and two propellant shut off valves. Charging valves and ports

and test valves and ports are provided at accessible points to permit

servicing, venting, purging and testing. The propellants are isolated in

the storage tanks by normally closed, pyrotechnic actuated valves ("C"

and "D" packages). Filters are provided in the "C" and "D" packages,

down stream of the isolation valves, to guard against contamination of

the thrust chamber assemblies.

The propellants used are:

- OXIDIZER - nitrogen tetroxide (N2O4) conforming to specification MIL - P - 26539 A

- FUEL - monomethyl hydrazine (N2H3CH3) conforming to specification MIL - P - 27404

Thrust Chamber Assembly (TCA) Group

The TCA group consists of thrust chambers and electrical solenoid valves. Sixteen TCA's are used per spacecraft (Figure 8-94 Above). Eight twenty-five pound thrust capacity TCA's are used for attitude control, (roll, pitch and yaw). Six one-hundred pound and two eight-five pound thrust capacity TCA's are used for translational maneuvering.

The pressurant tank contains high pressure helium (He) stored at 3000 PSI. (Figure Above). The tank is serviced through the "A" package high pressure gas charging port. Pressure from the pressurant tank is isolated from the remainder of the system by a normally closed pyrotechnic actuated isolation valve located in the "A" package. Upon command, the system isolation valve is opened and pressurized helium flows through the "E" package, to the pressure regulator, "B" package and propellant tanks. Normally, pressurant is controlled through system pressure regulator, and regulated pressure flows to the "B" package. The "B" package serves to deliver pressurant at regulated pressure to the fuel and oxidizer tanks, imposing pressure on the propellant tank bladder exteriors. Relief valves in the "B" package prevent over pressurization of the System downstream of the regulator. Burst diaphragms are provided in series with the relief valves, in the "B" package, to provide a positive leak tight seal between system pressure and the relief valve.

The "E" package provides a secondary mode of pressure regulation in

the event of regulator failure. In the event of regulator over-pressure

failure, resulting in excess pressure passage through the regulator, a

pressure switch ("E" package) intervenes and automatically closes the

normally open cartridge valve. Regulated pressure is then controlled

manually by the crew by momentary placing the OAMS REG switch in the

PULSE position. (Figure Above).

Control pressure information is obtained from the "B" package regulated

pressure transducer on spacecraft 5 and 6, the "F" package pressure

transducer on spacecraft 8 thru 12. Should

regulator under-pressure failure occur, the crew can manually select the

OAMS-REG switch to SQUIB. This selection opens the normally closed valve

and closes the normally open valve, thus pressurant by-passes the

regulator completely. Pressure is then regulated manually (OAMS-PULSE)

by the crew with control pressure information obtained from the "B"

package regulated pressure transducer on spacecraft 5 and 6, the "F"

package pressure transducer on spacecraft 8 thru 12. The "B" package

provides a division of pressurant flow to the propellant tanks. The

regulated pressure is sensed by the pressure transducer and provides a

signal to the

cabin instrument, (Figure Above)

indicating pressure downstream of the regulator. In the event of

regulator failure, the crew utilizes the reading to manually maintain

the required pressure in the system. Three check valves prevent back

flow of propellant vapors into the pressurant system. The "B" package

also affords a safety feature for prevention of over pressure on the

fuel and oxidizer tank bladders. Should the system be over pressurized

downstream of the regulator the over pressure would first rupture the

burst diaphragms, then he vented overboard through the relief valves.

The relief valves will reset when system pressure returns to normal.

On spacecraft 8 thru 12, the pressurant flows from the "B" package to the "F" package. The normally closed pyrotechnic valve in the "F" package is opened by placing the 0AMS RESV switch (Figure Above) in the SQUIB position, allowing pressurant to flow to the reserve fuel tank.

Fuel and oxidizer are stored in their respective tank: and are

isolated from the remainder of the system by normally closed pyrotechnic

valves in the "C" (oxidizer) and "D" (fuel) packages. Upon command, the

"A" (pressurant), "C" and "D" package isolation valves are opened. The

pressurant imposes )ressure on the propellant tank bladders and fuel and

oxidizer are distributed through their separate tubing manifold systems

to the inlet of the thrust chamber solenoid valves. Upon command on

spacecraft 8 thru 12, the normally closed pyrotechnic valve in the "F"

package is opened to allow pressurant to impose pressure on the reserve

fuel tank bladder

to distribute reserve fuel to the thrust chamber solenoid valve. Two

electrically operated motor control valves (Figure

Above) are located in the propellant feed lines, upstream of

the TCS's. In the event of fuel or oxidizer leakage through the TCA

solenoid valves, the motor operated valves can be closed by the crew to

prevent loss of propellants. The valves can again be actuated open by

the crew, when required, to deliver propellants to TCA solenoids.

Thrust Chamber Assembly (TCA) Group

Upon command from the automatic or manual controls, signals are

transmitted through the Attitude Control Maneuvering Electronics (ACME)

to selected TCA's to open simultaneously the normally closed,

quick-acting fuel and oxidizer solenoid valves mounted on each TCA. In

response to these commands, propellants are directed through all

injector Jets into the combustion chamber. The controlled l

fuel and oxidizer impinge on one another, where they ignite

hypergollcally to burn and create thrust. Heaters are connected to each

TCA oxidizer solenoid valve to prevent freeze-up and are activated by an

OAMS RTRS switch (Figure Above).

The helium pressurant is stored in welded, titanium spherical tank. Tank dimension is 16.20 inches outside diameter and has an internal volume of 1696.0 cubic inches. The helium gas is stored at 3000 psi rand held therein by the "A" package normally closed pyrotechnic actuated valve. The pressurized helium is used to expel the fuel and oxidizer from their respective tanks. Temperature sensors are affixed to the pressurant tank and outlet line to provide readings for the cabin instrument and telemetry.

The "a" package (Figure below)

consists of a source pressure transducer, isolation valve, two high

pressure gas charging _nd test valves and filters. The source pressure

transducer monitors tank pressure and transmits an electric signal to

the propellant indicator in the cabin and to the Instrumentation System.

The normally closed pyrotechnic isolation valve is used to isolate

pressure from the remainder of the system. The valve is actuated to the

open position to activate the system for operation. Two dual seal, high

pressure gas charging valves and ports are provided, one on each side of

the isolation valve. The upstream valve is used for servicing, purging

and venting the pressurant tank, while the downstream valve is used to

test downstream components. The valve

filters prevent system contamination during testing and servicing.

OAMS and RCS "A" Package and OAMS "F" Package Diagram

"F" Package (Spacecraft 8 thru 12 Only)

The "F" package (Figure Above) consists of a source pressure transducer, isolation valve, two high pressure gas charging and test valves and filters. The source pressure transducer monitors the regulated pressure and transmits an electrical signal to the cabin indicator and Instrumentation System, indicating the amount of regulated pressure for the OAMS system. The normally closed pyrotechnic valve is used to isolate the pressurant from the reserve fuel tank. The valve is actuated to the open position to activate the reserve fuel system for operation. Two dual seal, high pressure gas charging valves and ports are provided, one on each side of the isolation valve. The valve filters prevent system contamination during testing and servicing.

The "E" package (Figure Below)

consists of a filter, one normally open pyrotechnic actuated valve, one

normally closed pyrotechnic actuated valve, a normally closed two way

solenoid valve, a pressure sensing switch, and a manual by-pass valve.

The input filter prevents any contaminants from the "A" package from

entering the "E" package. The two pyrotechnic actuated valves are

activated (open to closed and closed to open) as required to maintain

regulated system pressure, in the event of system regulator malfunction.

The two way (open-close) solenoid valve is normally closed and functions

upon crew command to maintain regulated system pressure in the event of

a system regulator malfunction. The pressure switch senses regulated

pressure from the system regulator. Upon sensing over pressure, the

pressure switch intervenes and causes the normally open valve to actuate

to the closed position, closing the inlet to the pressure regulator. The

solenoid valve, when opened, allows pressurant flow through the package

after the normally opened valve is actuated to the closed position. The

manual by-pass (normal open) test valve is used to divert pressure to

the solenoid valve, during system test.

In the normal mode of operation, gas flows through the normally open pyrotechnic valve to the system regulator. In the event system regulator over pressure malfunction the pressure switch intervenes and causes the normally opened pyrotechnic valve to actuate to the closed position, diverting pressure to the normally closed solenoid valve. The solenoid valve is manually controlled (pulsed) by the crew to maintain regulated system pressure. In the event of system regulator (under pressure) malfunction 3 the normally closed pyrotechnic valve can be actuated to the open position. Simultaneously insured by the circuitry, the normally open valve is activated to the closed position. This prevents by-pass of the solenoid valve. In this mode, a regulator by-pass circuit is provided and pressure is regulated by the crew.

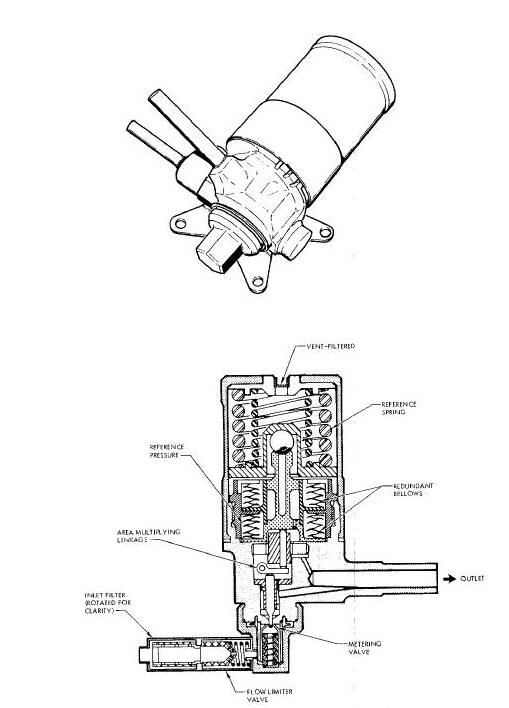

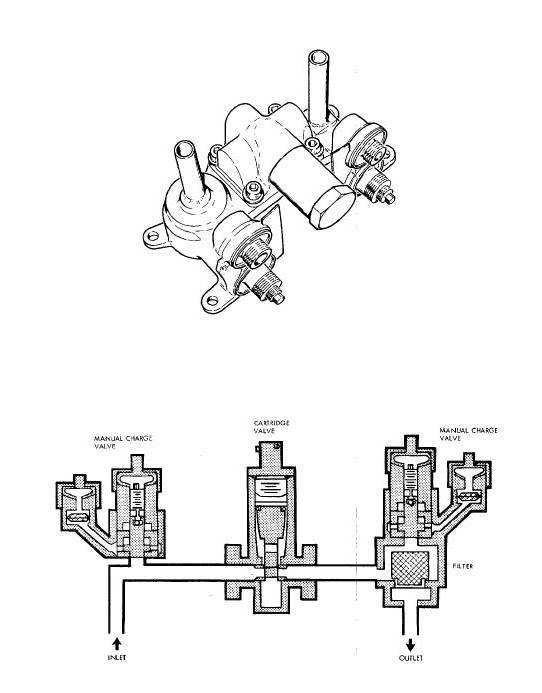

The pressure regulator (Figure below)

is a conventional, mechanical-pneumatic type. The regulator functions to

reduce the source pressure to regulated system pressure. An inlet filter

is provided to reduce any contaminants in the gas to an acceptable

level. An outlet llne is provided from the regulated pressure chamber to

the pressure switch ("E" package) and activates the switch in the

event of an over pressure malfunction.

OAMS and RCS Pressure Regulator Diagram

The "B" package (Figure Below) consists of filters, regulated pressure transducer, three check valves, two burst diaphragm, two relief valves, regulator out test port, fuel tank vent valve, Inter-check valve test port, oxidizer tank vent valve, and two relief valve test ports. The inlet filter reduces any contaminants in the gas to an acceptable level. Test valve inlet filters prevent any contaminants from entering the system. The regulated pressure transducer monitors the regulated pressure and transmits an electric signal to the cabin indicator and Instrumentation System, indicating the amount of regulated pressure on spacecraft 5 and 6. A single check valve prevents backflow of fuel vapors into the gas system. Two check valves are provided on the oxidizer side to prevent backflow of oxidizer into the system. The burst diaphragms are safety (over pressure) devices that rupture when regulated pressure reaches the design failure pressure, preventing excessive pressure from being imposed on the propellant bladders. The two relief valves are conventional, mechanical-pneumatic type with preset opening pressure. In the event of burst diaphragm rupture, the relief valve opens venting excess pressure overboard. The valve reseats to the closed position when a safe pressure level is reached, thereby, prevents venting the entire gas source. Manual valves and ports are provided to vent, purge and test the regulated system.

OAMS and RCS "B" Package Diagram

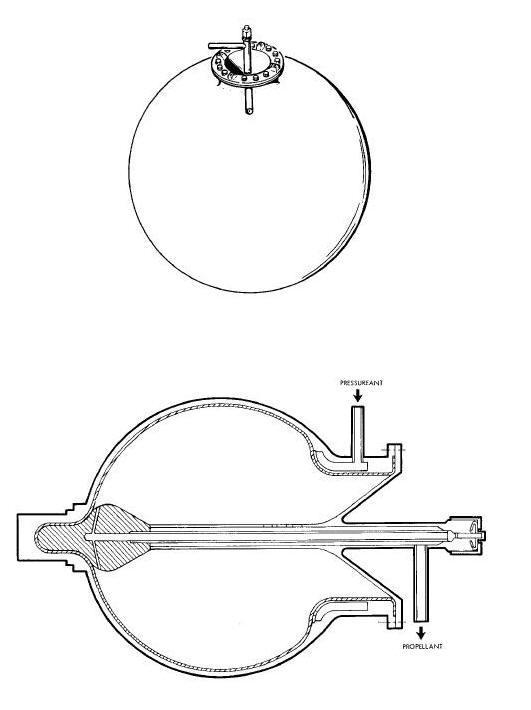

The fuel storage tank (Figure Below) is welded, titanium

spherical tank which contain an internal bladder and purge port. The

tank dimension is 21.13 inches in diameter, and has a fluid volume

capacity of 5355.0! cubic inches. The tank bladder is a triple layered

Teflon, positive expulsion type. The helium pressurant is imposed on the

exterior of the bladder to expel the fuel through the

"D" package to the thrust chamber solenoid valves. Purge ports are

provided to purge and vent the fuel tank. Temperature sensors are

affixed to the input pressurant line, fuel tank exterior and output line

to provide readings for the cabin indicator and Instrumentation System.

Reserve Fuel Tank (Spacecraft 8 thru 12 only)

The reserve fuel tank (Figure 8-102 Below) is a welded titanium cylindrical tank which contains an internal bladder and purge port. The tank is 5.10 inches outside diameter, 30.7 inches in length end has a liquid volume capacity of 546.0 cubic inches. The helium pressurant is imposed on the exterior of the bladder to expel fuel through the "D" package to the thrust chamber solenoid valves.

The oxidizer tank (Figure Above) is a welded titanium spherical tank which contain a bladder and purge port. The tank is 21.12 inches in diameter, and has a fluid volume capacity of 5355.0 cubic inches. The tank bladder is double layered Teflon, positive expulsion type. The helium pressurant is imposed on the exterior of the bladder to expel the oxidizer through the "C" package to the thrust chamber solenoid valves. Purge ports are provided to purge and vent the oxidizer tanks. Temperature sensors are affixed to the input pressurant line, oxidizer tank exterior and output line to provide readings for the cabin indicator and Instrumentation System.

The "C" (oxidizer) and "D" (fuel) packages (Figure

Below) are identical in function and are located downstream

of the tanks of their respective system. Each package consists of a

filter, isolation valve, propellant charging valve and test valve. The

filter is located at the outlet port to prevent contaminants from

entering the downstream system. The normally closed isolation valve is

used

to isolate propellants from the remainder of the system during the

pre-launch waiting period. The pyrotechnic isolation valve is actuated

to the open position for system operation. The propellant charging valve

is located upstream of the isolation valve and is used for servicing and

venting the system. The test valve is located downstream of the

isolation valve and is used to test the

downstream system.

OAMS and RCS "C" and "D" Package Diagram

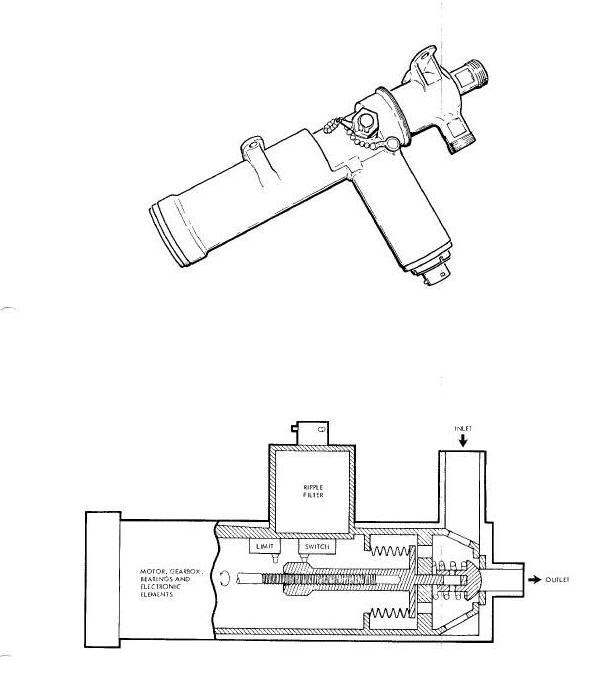

Propellant Supply Shutoff Valves

Propellant supply shutoff valves (Figure

Below) are provided for both the oxidizer and fuel system

and are located downstream of the "C" and "D" packages. The motor driven

shutoff valves are electrically operated and manually controlled. The

propellant valves serve as safeguards in the event of TCA leakage. The

valves are normally in the open position, and are closed at the option

of the

crew to prevent loss of propellants. The valve is thereafter reopened

only when it is necessary to actuate the TCA's for the purpose of the

spacecraft control.

OAMS and RCS Propellant Shutoff Valve Diagram

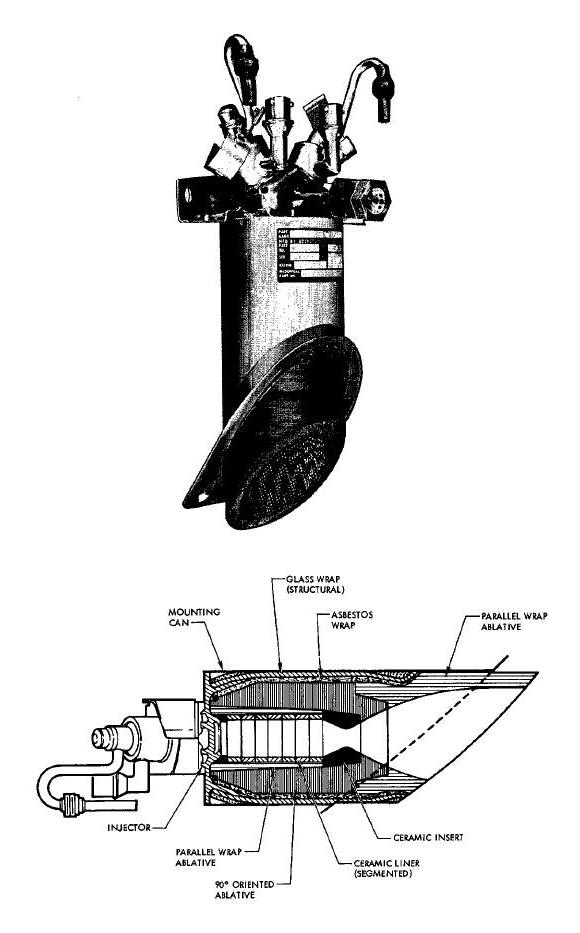

Thrust Chamber Assembly (TCA) Group

Each TCA (Figures for 25lbs. 85lbs. and 100lbs. Below) consists of two propellant solenoid valves, an electric heater, injection system, calibrated orifices, combustion chamber and an expansion nozzle. The propellant solenoid valves are quick acting, normally closed valves, which open simultaneously upon application of an electric signal. This action permits fuel and oxidizer flow to the injector system. The injectors utilize precise Jets to impinge fuel and oxidizer streams on one another for controlled mixing and combustion. The calibrated orifices are fixed devices used to control propellant flow. Hypergolic ignition occurs in the combustion chamber. The combustion chamber and expansion nozzle are lined with ablative materials and insulation to absorb and dissipate heat, and control wall temperature.

TCA's are installed within the adapter with the nozzle exits terminating flush with the outer moldline and located at various points about the adapter section suitable for the attitude and maneuvering control required. Electric heaters are installed on the TCA oxidizer lines to prevent the oxidizer from freezing.

The tubing cutter/sealer is a pyrotechnic actuated device and serves to positively seal and cut the propellant feed lines. Two such devices are provided for each feed line and are located downstream of the propellant supply on/off valve, one each in the retrograde and equipment section of the adapter. Prior to retrofire, the equipment section is Jettisoned. The devices are actuated to permit separation of the feed lines crossing the parting line, and to contain the propellants upon separation.

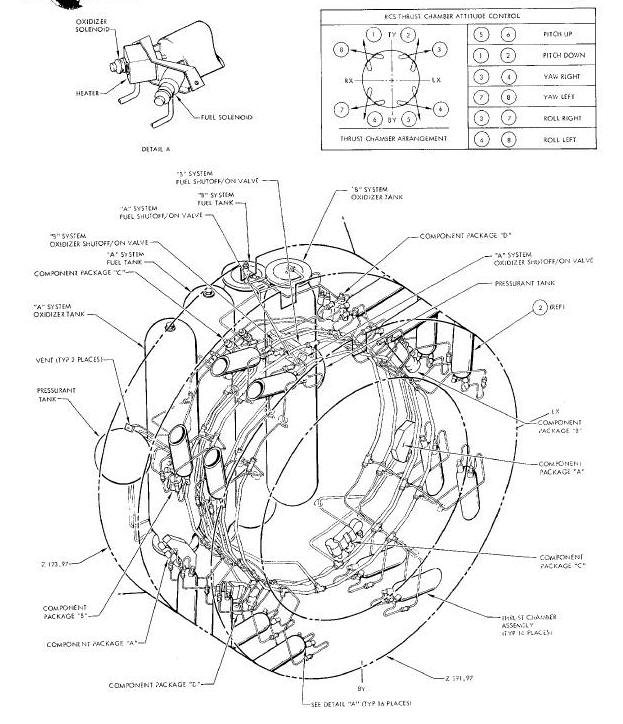

The Re-entry Control System (RCS) (Figure Below) is a fixed thrust, cold gas pressurized, storable liquid, hypergolic hi-propellant, self contained propulsion system used to provide attitude control of the spacecraft during re-entry.

NOTE: The RCS consists of two identical but entirely

separate and independent systems. The systems may be operated

individually or simultaneously. One system will be described, all data is

applicable to either system.

The RCS is capable of operating outside of the earth's atmosphere.

Re-Entry Control "A" and "B" Systems Diagram

Attitude control (roll, pitch and yaw) is obtained by firing the TCA's in groups. The TCA's are mounted at various points about the RCS section of the spacecraft consistent with the modes of rotational control required. The entire RCS, (tanks and control packages), with the exception of instrumentation, is located in the RCS section of the spacecraft. Each package consists of several functioning components and filters. The delivery of pressurants and propellants is accomplished by a uniquely brazed tubing manifold system. The HCS is divided into three groups; pressurant group, the oxidizer/fuel (propellant) group and the Thrust Chamber Assembly (TCA) group.

The pressurant group (Figure Below) consists of a pressurant tank, "A" package, pressure regulator and "B" package. Valves and test ports are provided at accessible points to permit servicing, venting, purging and testing. Filters are provided throughout the system to prevent system contamination. The pressurant is stored and isolated from the remainder of the system during pre-launch periods by a normally closed pyrotechnic actuated valve, located in the "A" package.

The fuel/oxidizer (propellant) group (Figure Above) consists of expulsion bladder storage tanks, "C" (oxidizer) and "D" (fuel) packages Valves, ports and test ports are provided at accessible areas to permit servicing, venting, purging and testing. Filters are provided throughout the system to prevent contamination. The propellants are isolated in the storage tanks from the reminder of the system by normally closed pyrotechnic actuated valves in the "C" and "D" packages. Heaters are provided on the "C" package to maintain the oxidizer at an operating temperature.

The propellants used are:

- Oxidizer - Nitrogen Tetroxide (N2O4) conforming to Specification MIL - P - 26539A

- Fuel - Monomethyl Hydrazine (_H3CH3) conforming to specification MIL - P - 27404

Thrust Chamber Assembly (TCA) Group

The TCA group (Figure Above) consists of eight twenty-five pound TCA's used for attitude (roll, pitch and yaw) control of the re-entry module. Each TCA is equipped with thrust chamber and electric controlled solenoid valves. Heaters are provided on the oxidizer solenoid valves to maintain the oxidizer at an operating temperature.

(Figure Above) High pressure

nitrogen (N2) (pressurant), is stored at 3000 psi in the pressurant

tank. The tank is serviced through the "A" package high pressure gas

charging port. Pressure from the pressurant tank is isolated from the

re-mainder of the system, until ready for operation, by a normally closed

pyrotechnic actuated valve located in the "A" package. Stored nitrogen

pressure is monitored and transmitted to the cabin indicator and

Instrumentation System by the source pressure transducer located in the

"A" package. Upon command, the "A" package pyrotechnic actuated valve is

opened (simultaneously with propellant "C" and

"D" package pyrotechnic actuated valves) and nitrogen flows to the

pressure regulator and "B" package. The "B" package provides a division

of flow to the propellant tanks. The regulated pressure is sensed by the

regulated pressure transducer ("B package) and provides a signal to the

Instrumentation System, indicating pressure downstream of the regulator.

The check valves prevent backflow

of propellant vapors into the pressurant system. The "B" package also

provides a safety feature to prevent over pressure of the fuel and

oxidizer tank bladders. Should the system be over pressurized downstream

of the regulator the over pressure would first rupture the burst

diaphragms then be vented overboard through the relief valves.

Fuel and oxidizer (propellants) are stored in their respective tanks,

and are serviced through the high pressure charging ports in the "c" and

"D" packages. The propellants are isolated from the remainder of the

system, until ready for operation, by the normally closed pyrotechnic

valves in the "C" and "D" packages. Upon command the "A" (pressurant),

"C" (oxidizer) and "D" (fuel) package pyrotechnic

actuated valves are opened and propellants are distributed through their

separate tubing manifold system to the thrust chamber inlet solenoid

valves.

Two motor driven shutoff valves are located in the propellant feed

lines, upstream of the TCA's. In the event of fuel or oxidizer leakage

through the TCA solenoid valves, the motor operated valves can be closed

by the crew to prevent loss of propellants. The valves can again be

actuated open by the crew, when required, to deliver propellants to the

TCA solenoids. Heaters are connected to

the output lines of the "C" and "D" packages and are activated by the

RCS HTR switch (Figure Above).

Thrust Chamber Assembly (TCA) Group

Upon command from the automatic or manual controls, signals are transmitted through the Attitude Control Maneuvers Electronics (ACME) to selected TCA's to open simultaneously, the normally closed, quick acting fuel and oxidizer solenoid valves mounted on each TCA. In response to the signals, propellants are directed through small injector Jets into the combustion chamber. The controlled fuel and oxidizer impinge on one another where they ignite hypergolically to burn and create thrust. Heaters are connected to each TCA oxidizer solenoid valve to prevent freeze-up and are activated by the RCS H_ switch (Figure Above).

The nitrogen (N2) pressurant is stored in a welded, titanium spherical tank. The tank is 7.25 inches outside diameter and has an internal volume of 185.0 cubic inches. Nitrogen gas is stored at SO00 _si and held therein by the "A" package pyrotechic valve. This nitrogen, under pressure, is used to expel the fuel and oxidizer from their respective tanks. Temperature sensors are affixed to the pressurant outlet line to provide readings for the cabin instrument and telemetry.

The "A" package (Figure Above)

consists of a source pressure transducer, isolation valve, filters and

two high pressure gas charging valves. The source pressure transducer

monitors the stored pressure and transmits an electric signal to the

cabin indicator indicating the pressure of the stored gas. The normally

closed isolation valve is used to isolate the pressure from the

remainder of the

system.

The valve is pyrotechnically actuated to the open position to activate the system for operation. Two dual seal, high pressure gas charging valves and ports are provided, one on each side of the isolation valve. The upstream valve is used for servicing, venting and purging the pressuraut tank, while the downstream valve is used to test downstream components. Filters are provided to prevent contaminants from entering the system.

The pressure regulator (Figure Above) is a conventional , mechanical-pneumatic type. The regulator functions to reduce the source pressure to related system pressure. An inlet filter is provided to reduce any contaminants in the gas to an acceptable level.

The "B" package (Figure Above) consists of filters, regulated pressure transducer, three check valves, two burst diaphragms, two relief valves, regulator output test port, fuel tank vent valve, oxidizer tank vent valve, inter-check valve test port and two relief valve test ports. The inlet filter reduces any contaminants in the gas to an acceptable level. Valve inlet filter prevent contaminants from entering the system. The pressure transducer monitors the regulated pressure and transmits an electrical signal to the spacecraft Instrumentation System. A single check valve prevents backflow of fuel vapors into the gas system. Two check valves are provided on the oxidizer side to prevent backflow of oxidizer vapor into the gas system. The Burst diaphragms are safety devices that rupture when the regulated pressure reaches the design failure pressure, preventing excessive pressure from being imposed on the propellant bladders.

The two relief valves are conventional mechanical-pneumatic type with

preset opening pressure. In the event of burst diaphragm rupture, the

relief valve opens, venting excess pressure overboard. The valve reseats

to the closed position when a safe level is reached, preventing the

entire gas source from being vented overboard. Manual valves and ports

are provided to vent, purge and test

the regulated system.

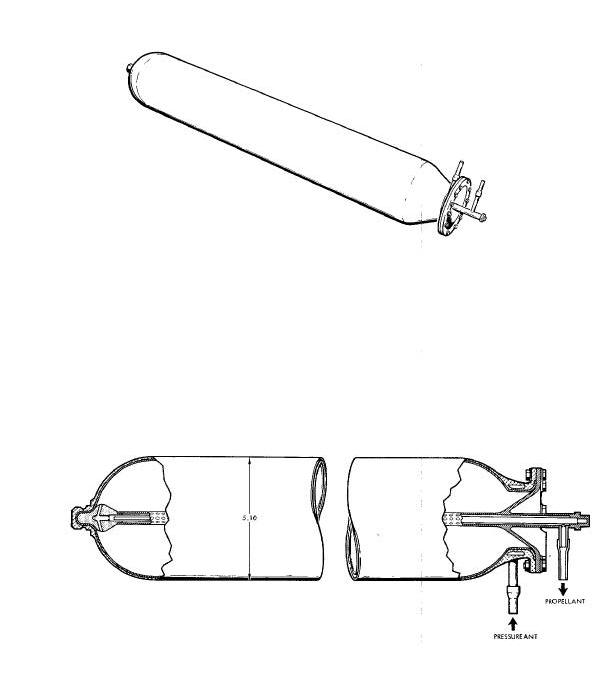

The fuel tank (Figure Above)

is a welded, titanium cylindrical tank which contains an internal

bladder and purge port. The tank is 5.10 inches outside diameter, 30.7

inches in length and has a fluid volume capacity of 546.0 cubic inches.

The nitrogen pressurant is imposed on the exterior of the bladder to

expel fuel through the "D" package to the TCA solenoid valves. The purge

port is provided

to purge and vent the fuel tank bladder. Temperature sensors are affixed

to the nitrogen input line and fUel output line to transmit signals to

Instrumentation System.

The oxidizer tank (Figure Above) is a welded, titanium cylindrical tank which contains a bladder and purge port. The tank is 5.10 inches outside diameter, 25.2 inches in length and has a fluid volume capacity of 439.0 cubic inches. The bladder is a double layered Teflon, positive expulsion type. The nitrogen pressurant is imposed on the exterior of the bladder to expel the oxidizer through the "C" package to the TCA solenoid valve. The purge port is provided for purging and venting the oxidizer tank bladder. Temperature sensors are affixed to the nitrogen input line and oxidizer output line to transmit signals to Instrumentation System.

The "C" and "D" packages (Figure

Above) are identical in function and are located downstream of

the tanks of their respective system. Each package consists of filters,

an isolation valve propellant charging valve and test valve. The filter,

located at outlet ports reduces contaminants tO an acceptable level. The

valve and port filters prevent contaminants from entering the system.

The normally

closed isolation valve is used to isolate propellants from the remainder

of the system during the pro-launch period. The isolation valve is

pyrotechnic actuated to the open position for system operation. The

propellant charging valve is located upstream of the isolation valve and

is used for servicing and venting the system. The test valve is located

downstream of the isolation valve and is used to test the downstream

system.

Propellant Supply Shutoff Valves

Propellant supply shutoff valves (Figure Above) are provided for both the oxidizer and fuel system, and are located downstream of the "C" and "D" packages in the system. The motor driven shutoff valves are electrically operated, and manually controlled. The valves are normally in the open position, and are closed at the option of the crew to prevent loss of propellants. The valves are reopened only when the TCA's are needed for spacecraft control.

Each TCA (Figure 8-110 Below) consists of two propellant valves, injection system, calibrated orifices, combustion chamber and expansion nozzle. The fuel and oxidizer solenoid valves are quick acting, normally closed valves, which open simultaneously upon application of an electric signal. The action permits fuel and oxidizer flow into the injector system. The injectors use precise Jets to impinge fuel and oxidizer streams on one another for controlled mixing and combustion. The calibrated orifices are fixed devices used to control propellant flow. Hypergolic ignition occurs in the combustion chamber. The combustion chamber and expansion nozzle is lined with ablative materials and insulation to absorb and dissipate heat and control external wall temperature. TCA's are installed within the RCS section mold line, with the nozzles terminating flush with the outer mold line. TCA's are located at fixed points in the RCS section in a location suitable for attitude control. Electric heaters , located on the oxidizer valve, are used to prevent the oxidizer from freezing.

RCS 25 Lbs.TCA Diagram

A

ACME - Attitude Control Maneuvering Electronics (ACME)

O

OAMS - Orbit Attitude and Maneuvering System (OAMS)

R

RCS - Re-entry Control System (RCS)

T

Thrust Chamber Assemblies (TCA)